Klingenburg UV HIGH FLOW to urządzenia zaprojektowane z myślą o instalacjach wentylacyjno-klimatyzacyjnych o wysokich wartościach przepływu powietrza. Są to urządzenia przeznaczone do montażu w kanałach wentylacyjnych bądź w sekcjach central klimatyzacyjnych.

HIGH FLOW

TECHNOLOGY

Klingenburg UV HIGH FLOW - devices designed with a thought of ventilation-air-conditioning installations with high values of airflow. These devices are designated for assembly inside ventilation ducts or in air handling unit sections.

HIGH FLOW

TECHNOLOGY

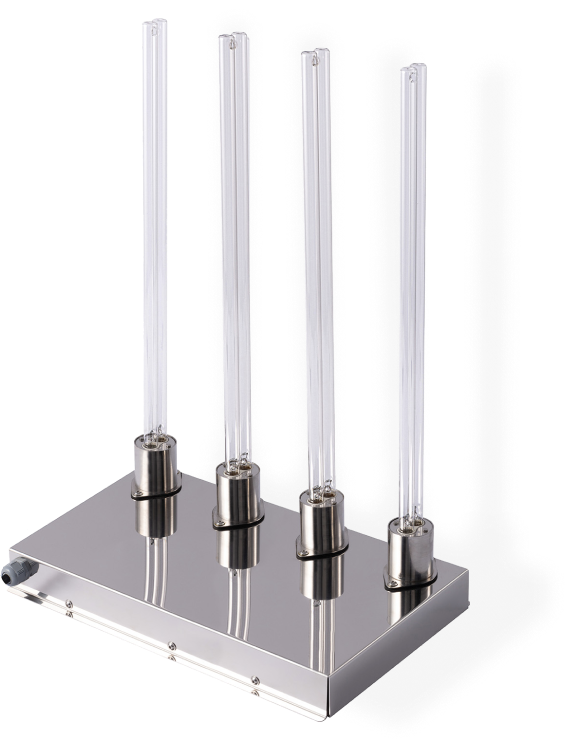

A complete high Flow module (MSD) contains:

Disinfection modules with lamps and ignition systems and a lamp work time counter.

The module housing is made of high-quality stainless steel (grade 1.4301). The applied ignition systems ensure a warm ignition of the lamps with warming up the electrodes. An electrical counter is used to measure the lamp lighting time. Its work is correlated with the work of modules in order to identify the work time of the device which directly impacts the device warranty conditions. The number of modules is determined by the conducted selection for a given application. A single High Flow module may contain between 1 and 4 lamps as a maximum.

The assembly of High FLOW UV-C modules in the air handling unit may be realized in two ways (the choice here depends solely on the location and the possibilities of mounting inside the air handling unit section): with the use of sheet-metal screws or a sliding guide to which UV-C modules are inserted. In case of assembling UV-C lams on the ventilation duct it is necessary to carry out initial works, that is, the insulation of the duct in the assembly location, preparation of the window and of the assembly holes before placement of a board on which UV-C lamps will be mounted.

UC-V

EMITTER

Emitters applied in devices from the Klingenburg UVC TECHNOLOGY line include:

Highest-quality components

Lifecycle amounts to: 8000 - 1200 hours

Equipped in electronic ignition systems which ensure warm ignition, thus, prolonging the device lifecycle

Power adjusted to the used application: 60 and 95 W.

TYPE OF EMITTERS

Depending on the place of installation, temperature of the disinfected air and type of industry, we apply one of the three following types of emitters for our devices:

UV securer

Emitters wrapped in a teflon film which transmits UV-C radiation. Thanks to the film, in case of damages in the emitter, glass dust is stopped inside the film.

UV standard

Emitters without additional protection, designated for operations in standard conditions.

At Klingenburg we focus on the continuous development, research and elaboration of innovative technologies that may serve for the benefit of society and the environment on a daily basis. Experience gained worldwide, through many years of working in several branches of industry has taught us that even upon applying strict hygiene principles, once the air passes through the ventilation-air-conditioning installation it will always carry a large portion of microbiological impurities. As a result of inhaling contaminated air, the health of indoor premises users is exposed each day!

Bearing in mind and agreeing with the statement of the World Health Organization: “Everyone has the right to breathe clean indoor air”